At Steinmetal, we offer a complete line of refractory vibrocompaction equipment designed to ensure fast, uniform, and safe installation of refractory concretes in induction furnaces. With our technology, clients achieve higher density, lower porosity, and extended lining life.

| Equipment | Vibration Frequency | Centrifugal Force / Impact | Energy / Air Consumption | Capacity / Application |

|---|---|---|---|---|

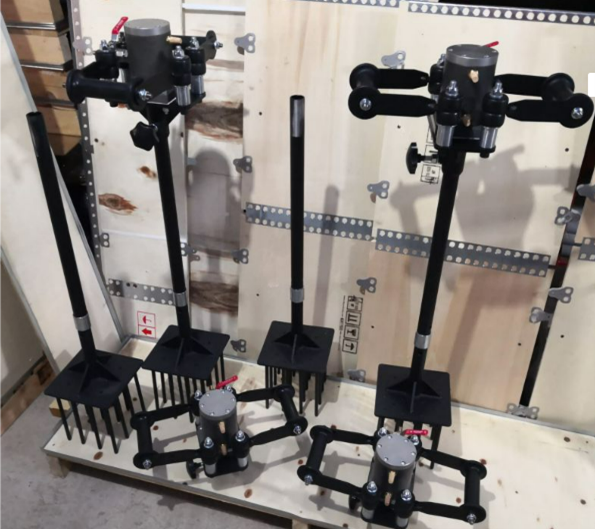

| 2 Piston Rotary Vibrator | 3,000 – 6,000 rpm | 1,200 – 2,000 N | 3.5 kW electric | Medium linings |

| 3 Piston Rotary Vibrator | 3,500 – 7,000 rpm | 1,800 – 3,200 N | 4.5 kW electric | Large linings |

| Floor Vibrating Plate | 50 – 70 Hz | 1,500 – 2,500 N | 3.0 kW electric | Foundations and base layers |

| Pneumatic Tamper | 800 – 1,200 blows/min | 30 – 50 Joules/blow | 0.5 – 0.7 m³/min air | Critical/localized areas |

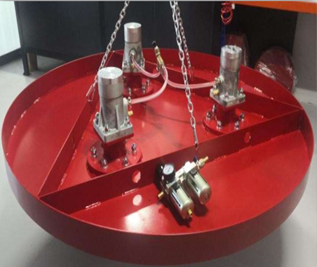

| PLC Lifting System | – | – | 2.0 kW electric | Up to 3,000 kg load |

Values may vary depending on the model and configuration requested.

| Operational Benefits | Industrial Applications |

|---|---|

| Higher density and strength of refractory concrete. | Medium and high-frequency induction furnaces. |

| More durable linings, reducing maintenance needs. | Ferrous, non-ferrous casting, and steelmaking processes. |

| Reduced installation time, optimizing plant shutdowns. | Ladle linings and auxiliary equipment. |